Acrylic sheets are well-known and utilized for DIY ( Do-It-Yourself) projects and acrylic craft projects such as acrylic fish tanks, acrylic display boxes, etc. They are widely utilized due to their ease of use and quality. With small details to the work, you can develop useful acrylic storage boxes in hours. Acrylic Company in Dubai offers the best Acrylic material to let you deploy them on various products like Acrylic furniture, acrylic cosmetic boxes, acrylic display, acrylic roofing sheets, and many more.

Also known as Plexiglass, acrylic can also be purchased online or obtained from the Acrylic Fabricators in Dubai. Though the acrylic storage boxes are readily available, you can also make it a part of your hobby to make personalized acrylic boxes. Acrylic sheets come in different thicknesses and colors. If you consider a waterproof box or a fish tank, you should purchase acrylic sheets with a minimum ¼ inch thickness.

Table of Content

What is An Acrylic Box

Acrylic boxes can be a fun and creative piece for your walls, tables, floors, ceilings, or shelves. These boxes look attractive and come in varying shapes and colors. You can choose the box that you like the most. They can either carry stuff or just be art pieces.

You can easily create a budget-friendly acrylic display box using Plexiglass. Unlike conventional glass, which used to break and leave sharp edges while being dropped, acrylic is built to exhibit shatter resistance. It has a composition of PMMA (Polymethylmethacrylate) and is usually used for display cases, window panes, and solar panels due to its lightweight and excellent weather resistance. The homemade acrylic box can be used to display your valuables, cosmetics, awards, and so on.

Have you ever thought about building a spectacular DIY acrylic box by yourself? If yes, look no further!

If you have an acrylic sheet you can make a box out of it. An acrylic box can be transparent or can come in any color that you like. In this post, we will learn how to create the acrylic box. Do check every detail that we have gathered in this post for you.

What are the Different Types of Acrylic Boxes

Before you learn about how to make an acrylic box, you must learn more about them. This helps you to find the box that you want to make. Different types of acrylic boxes come in the way they serve a purpose. The boxes can be transparent or colorful or multi-colored. Such boxes can either have thick sheets or moderately thick sheets. These boxes can be jewelry boxes, stationery boxes, food boxes, or make-up boxes. You can also make an acrylic flower box. And of course, they also make great display boxes. Display boxes display any food or product. They can also be game boxes, mystery boxes, or gift boxes. You can also avail yourself of the acrylic material for acrylic boxes in the UAE from the best acrylic companies.

How to Make an Acrylic Box

Step 1: Gather the necessary supplies

Collect the essentials you need to make the acrylic storage boxes. Here are the core materials you must have before you begin to make the acrylic display box.

- Acrylic Sheets

- X-acto Knives

- Stainless Steel Scale or Rulers

- Super Glues

- Mats for Making Cuts

Step 2: Drilling Plexiglass

Here is the next step for a DIY acrylic display case-making process. Depending on the thickness of the sheet you have the job of cutting the sheet will be of varying exertions. If not appropriately drilled, Plexiglass will form cracks. It is necessary to drill the specific holes for the hinge screws if you wish to create an acrylic display case that opens. To avoid cracks, make use of a plexiglass drill built with 600 tips to function better with the hard plastics. Finally, lubricate the drill with mineral oil to let it drill smoothly.

Here are the steps to begin with your acrylic cutting process:

- Put the sheet that you chose for the custom acrylic display case on any flattened area.

- Firmly place the stainless steel scale on the sheet and start to press.

- Pressing tightly begins to cut the sheet precisely.

- First, create three or five cuts through the scale on the sheet.

- Change the side of the sheet.

- Now repeat the same cutting process using the stainless steel scale pressed tightly on the sheet.

- Be careful here you need to watch the cuts properly and cut only on the cuts to get better results.

- Create three or five cuts. These cuts must be placed deeply into the acrylic sheet. You can apply plenty of pressure on the scale to make professional cuts.

- Next, you can see that as you apply more strength the sheet starts to break from the cuts that you made. Success!

- Once you get those parts that you need for making acrylic boxes, you will see how great this cutting process is.

To know more about acrylic cutting and engraving, check out the detailed guide on the link.

Step 3: Sanding process

Before settling to try to learn how to build a plexiglass box, you must create an order. Here you must place all the pieces on the table. Check if you need to sand any parts if there are uneven edges or scratches on the sheet parts. Also, keep an eye on the tips to remove scratches from the acrylic sheets to maintain appearance and quality.

Organize the acrylic sheets initially. You can also scrutinize for possible defects and smoothen the areas using the sanding process. Wash the sheets properly using the right materials. Be careful not to damage the quality of the pieces, now the pieces are ready to use.

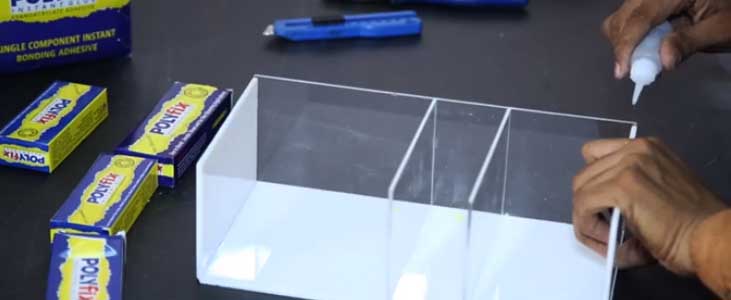

Step 4: Glue the pieces properly

Now here you need a good quality super glue to build a waterproof acrylic box. Place the bottom piece on the table. Glue on one side of the bottom square piece. Start to place the second piece on that one side on the bottom piece that carries the glue. Check if the piece has enough glue. Place the piece firmly on the bottom piece till the piece stands by itself.

Once you find that the piece has stuck well, move to fix the next piece. Next, glue the two sides of the second piece and fix one side on the bottom and the next side on one side of the second piece that we stuck earlier. In this way, you get a corner of the box. Use the same gluing instructions as in the first two pieces.

Place firmly until the pieces are stuck properly. Then, move to add the fourth piece to the box. Check if the glue is used properly. Firmly stick all the rest of the pieces until you get an uncovered box out of it. In total, you must have used five pieces to get an uncovered acrylic box.

If you wish, use the next sixth piece to cover the uncovered upper part of the box. Place glue on all edges of the part and seal the top of the box precisely. Apply only the right pressure. In this way, you will get a complete acrylic box.

Want tips on how to care for and maintain your acrylic products for long life? Check the link given.

Hinge technique to make an Acrylic display box

In this guide on how to make acrylic box sets, let us also understand the popular hinge technique used to make acrylic display boxes.

For the detailed step-by-step guide, here you go:

- Cut 90-degrees V-grooves all the way along the rectangular acrylic sheet with one groove placed parallel and equidistant from all sides.

- Apply the strips of the solvent-proof tape or adhesive to the ungrooved plastic end a strip centered and every way along the groove.

- Bend the plastic and snap at each groove. Now the tape strips form hinges.

- The tiny squares of waste plastic along the corners are removed, and the couple parts of the interfering tape are cropped away using a razor.

- The sides of the acrylic box are folded through the hinges. Strips of tape are pasted on the four ends to hold the stuff in place.

- Apply solvent cement along the mitered edges, and after it sets, the tape can be removed to get the completed box.

You can also bend acrylic products to amazing shapes as you wish. To know about this, read our blog.

Benefits of Acrylic Boxes

Acrylic boxes can be used for a wide variety of purposes, since they are transparent, clear, and offer great quality for a long time. Here are the benefits that can make acrylic boxes your all-time favorite.

- These boxes are compact and highly portable

- They are waterproof

- The box cannot break easily as glass do

- They are powerful and can hold properly in every weather

- They can be used as artworks for your homes or office spaces

- They serve as carriers of stationery products like pens, scissors, glue, pencils, notes, and other stuff

- These boxes can be used as gifts and decorative items

- You can also use them to cover lights like a lampshade or acrylic lightbox

- You can store valuables in the boxes

- Some people use it as a makeup box, display tray, or jewelry box

- While others use it to store hobby items like buttons, sewing needles, and craft stuff.

In short, you can use it for anything that a box can be used for. To get a detailed understanding of the benefits acrylic plastic offers.

Wrap Up

In this post above we have mentioned one way of creating an acrylic box at your home or workplace. Kindly read the whole post properly to get better results. We have painstakingly collected valuable instructions about building an acrylic box. This is a Do It Yourself guide to making an acrylic box. Hoping you would use these tips correctly. You can also have a look at the exciting DIY craft projects using acrylic.

Pleasant Acrylic is an acrylic manufacturing company that provides acrylic service and fabrication in Dubai, United Arab Emirates, specializing in POP exhibits. The group is run by a leadership team to capture the large acrylic market in the UAE through service excellence, service, good Acrylic Design UAE, and excellent satisfaction. For more details about Acrylic Box Dubai and various other acrylic products, click here.

Frequently Asking Questions

1. How do you waterproof an acrylic box?

Though acrylic is slightly water-resistant, it doesn’t offer a complete waterproof feature. To make acrylic waterproof, include a sealer over the acrylic paint. You can also prepare the surface to be painted well in advance for the best results.

2. Does acrylic yellow over time?

The acrylic is derived from natural gas and is fully inert while in solid form. The strong and pure acrylic does not yellow in the light. Be choosy and go for a reliable acrylic supplier in Dubai, like Pleasant Acrylic, who can offer the best acrylic design and acrylic fabrication services with superior quality.

3. How strong is acrylic?

How strong is acrylic?

The tensile strength of acrylic exceeds 10,000 lbs./square inches and offers high-end impact resistance, i.e. 6 to 17 times more than normal glass. Hence, it doesn’t shatter and, if it breaks, it cracks into large, dull-edged parts.