Acrylic Laser Cut: Everything You Need to Know

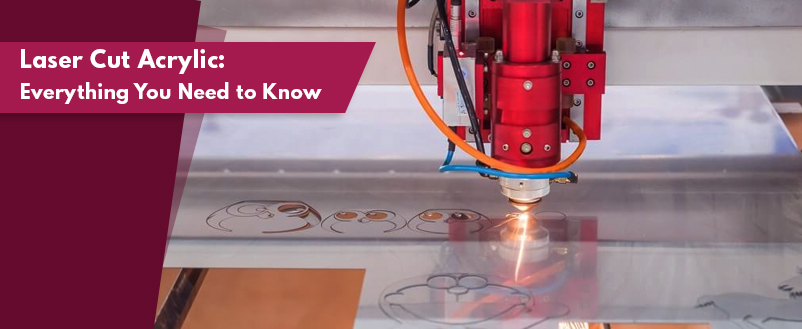

Acrylic laser cutting is a manufacturing process in which a laser beam is used to cut through acrylic material. It is performed using an acrylic laser cut and the laser beam is directed at the acrylic sheet. Then, the heat from the laser melts and vaporises the fabric, leaving behind a precise cut. Laser cutting is a versatile and efficient way to cut acrylic, and it can be used to produce a wide range of products, including signage, displays, point-of-purchase displays, awards, trophies, and more. Laser-cut acrylic is acrylic that has been cut using a laser cutter. Laser cutting is a precise and efficient way to cut acrylic, and it can be used to produce complex shapes and designs. Laser acrylic cut final products are also durable and easy to clean, making them ideal for various applications.

Types of Acrylic

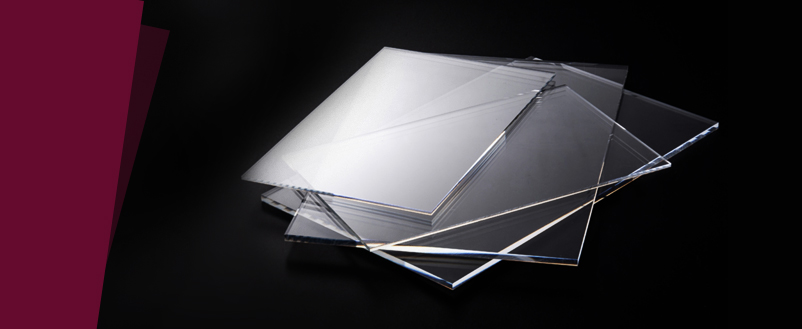

Acrylic is a widely used versatile material and it has two primary forms: cast acrylic and extruded acrylic. If you require or are going to perform laser cutting acrylic, then you should be aware of the difference.

- Cast Acrylic: Cast acrylic also known as cell cast acrylic is manufactured by a casting process. It involves pouring a liquid acrylic resin into moulds and allowing it to solidify. This method produces high-quality acrylic sheets with exceptional clarity and minimal internal stress.

Key Points:- Excellent Optical Clarity: Cast acrylic is renowned for its exceptional transparency and optical clarity. This acrylic fabrication is a preferred choice for applications where aesthetics and visibility are vital such as museum displays and acrylic photo frames.

- Easy to Machine: Due to its low internal stress, cast acrylic is easier to work with including using an acrylic cutter or laser cutting machine for acrylic. It is less likely to crack or warp during machining, resulting in clean, precise cuts.

- High Cost: The manufacturing process and superior quality of cast acrylic make it relatively more expensive than extruded acrylic.

- Extruded Acrylic: Extruded acrylic, on the other hand, is produced by extruding acrylic polymer through a die, followed by cooling and shaping. This process yields acrylic sheets with good optical properties, though not as high as cast acrylic.

Key Points:- Cost-Effective: Extruded acrylic is a cost-effective alternative to cast acrylic, making it suitable for projects where budget constraints are a concern.

- Optical Clarity: While not as optically clear as cast acrylic, extruded acrylic still offers good transparency, making it suitable for applications like signs, POP displays, and protective barriers.

- Slightly More Brittle: Extruded acrylic may be slightly more brittle and prone to stress cracking, particularly when subjected to external forces during cutting or machining.

Key Properties of Acrylic

Understanding the key properties of acrylic is essential when considering its use in various applications, whether it’s for laser cutting or any other project.

- Transparency and Clarity: Acrylic is prized for its exceptional transparency and optical clarity. It allows up to 92% of visible light to pass through, making it an ideal choice for projects where visual aesthetics are crucial.

- Durability: Acrylic is remarkably durable. It is shatter-resistant, making it a safer alternative to glass. Its durability also extends to impact resistance, making it suitable for applications where it may be exposed to moderate physical stress.

- Weather Resistance: Acrylic exhibits excellent weather resistance. It can withstand UV exposure without significant degradation, making it a preferred material for outdoor applications such as signage and protective barriers.

Acrylic Laser Cut Applications in Dubai

This remarkable material, also known as PMMA (Poly Methyl Methacrylate), has become an integral part of the city’s aesthetic and functional infrastructure. From eye-catching acrylic name boards to elegant acrylic podiums and cosmetic boxes. The demand for Acrylic design in Dubai is growing each year as the commercial industry is fast-moving.

1. Acrylic Name Boards: Acrylic name boards have become a ubiquitous sight in Dubai’s corporate world. Their sleek and modern appearance makes them ideal for displaying business names and logos. Acrylic’s durability ensures that these nameboards can withstand Dubai’s extreme weather conditions and maintain their elegance for years.

2. Acrylic Podiums: From conferences to presentations, acrylic podiums in Dubai offer a clear and unobtrusive platform for speakers. They exude a sense of sophistication and professionalism that aligns perfectly with Dubai’s image as a global business hub. Their transparency allows speakers to maintain a connection with the audience while presenting their ideas.

3. Acrylic Cosmetic Boxes: The cosmetic industry in Dubai places a premium on aesthetics. Acrylic cosmetic boxes in Dubai combine functionality with visual appeal. They not only provide a clear view of the products but also protect them from dust and contamination. These boxes are a must-have for retailers looking to showcase their products attractively.

4. Acrylic Boxes: Acrylic boxes serve various purposes in Dubai, from product displays in retail stores to protective cases for valuable items. Their transparent nature allows for easy visibility, making them perfect for collections, retail merchandise, or even as storage containers in homes.

5. Acrylic Stands: Acrylic stands have become an essential accessory in exhibitions, trade shows, and retail outlets across Dubai. They offer a clean and unobtrusive way to showcase products, brochures, or promotional materials, ensuring the focus remains on what’s being presented.

6. Acrylic Glass: Acrylic glass, often used interchangeably with Plexiglas or Perspex, has become the go-to alternative for traditional glass in Dubai’s architectural and interior designs. It offers the advantage of being shatter-resistant, lightweight, and highly transparent, making it perfect for windows, partitions, and decorative elements.

7. Acrylic UV Printing: Acrylic UV printing technology has revolutionized the way businesses and individuals in Dubai customize acrylic surfaces. This process enables high-resolution, full-colour printing directly onto acrylic, enhancing the visual appeal of signs, displays, and promotional materials.

8. Acrylic Signage: Acrylic signage is widely used for both indoor and outdoor applications in Dubai. Its durability, weather resistance, and aesthetic appeal make it a popular choice for businesses looking to make a strong impression with their signage.

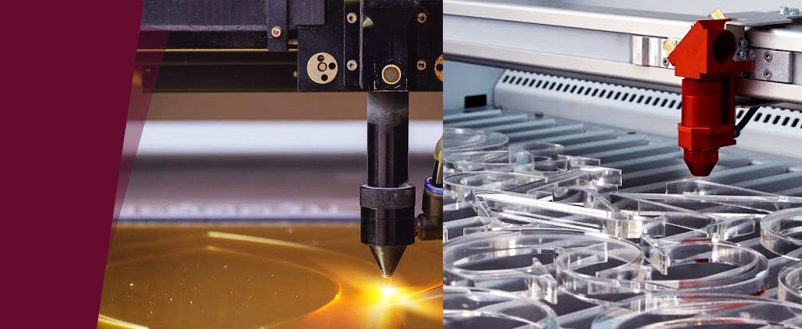

Process of Laser cutting

Laser cutting is a precise and versatile process used to shape and engrave various materials. Understanding the laser-cutting process is crucial for achieving accurate and high-quality results. Here’s a breakdown of the key steps involved:

A. Setting Up the Laser Cutter: This step involves configuring the machine for acrylic cutting for the specific material and design. Operators set the power, speed, and focal length to ensure the laser beam cuts accurately. Proper ventilation and safety measures are also essential during setup.

B. Calibrating the Laser Cutter: Calibration ensures that the laser cutter’s focus is accurate. This involves adjusting the laser head’s position and ensuring that it maintains a consistent distance from the material surface, which is critical for precision cutting.

C. Material Fixturing: Fixturing involves securely positioning the material to be cut within the laser cutter. This can include using clamps, pins, or vacuum tables to prevent material movement during the cutting process, ensuring precision and repeatability.

D. Running the Laser Cutter: Once calibrated and fixtured, the laser cutter is ready to run. The laser follows the programmed path, cutting through the material with high precision. The operator monitors the process to ensure everything runs smoothly.

E. Post-Cutting Steps: After cutting acrylic sheet is complete, post-processing may be necessary. This can include removing any residual burrs, cleaning the cut edges, and inspecting the workpiece for quality. Some materials may require additional finishing steps such as sanding or polishing to achieve the desired appearance.

Mastering each step of the laser cutting process is crucial for achieving accurate, high-quality results in various applications, from intricate designs in acrylic to precise metal components in engineering.

Conclusion

We’ve talked a lot about laser-cut acrylic, which is a versatile material. We discussed the two main types of acrylic and its special qualities like being see-through, strong, and able to withstand weather. We also looked at many ways people use acrylic, like making name boards, cosmetic boxes, podiums, and more, especially in a dynamic place like Dubai where they love modern designs. If you’re interested in working with laser-cut acrylic, don’t be afraid to give it a try. It’s like a blank canvas for your creative ideas. To learn more, you can check out local places in Dubai that work with acrylic, ask questions in online communities, or find tutorials and suppliers who can help you get started. In simple terms, laser-cut acrylic is a cool material that lets you create amazing things, and there are lots of ways to learn and get better at it, whether you’re in Dubai or anywhere else. So, go ahead and explore this exciting world of acrylic!

FAQ

In addition to regular acrylic products, Pleasant Acrylic also manufactures top-quality acrylic domes in Dubai and acrylic balls in Dubai. Our team provides sound support for all of our branded products, so maintenance is easy. We hope that our products will make your life more convenient and comfortable. Contact us for more information.

Yes, acrylic domes are durable and can withstand outdoor conditions when properly installed and maintained.

Acrylic shapes can be bonded using special acrylic cement that melts and fuses the material together.

The thickness depends on the dome’s size and use — typically ranging from 3mm to 10mm for strength and durability.