In a constantly evolving and advancing world, what binds the generations together is the love for aesthetically appealing products that manifest productivity in every sense. Acrylic products have already acquired a position in the list and are eternally continuing to be a popular and highly acknowledged innovation from day one of their inventions. Albeit the limitations of acrylic sheets during their earlier stages where it was only used as safety glasses, the Acrylic Fabricators in Dubai have recognized and exploited the versatility of acrylic products and their variety of applications over the years. Pleasant Acrylic is an Acrylic Company in Dubai that offers a wide range of acrylic materials with diverse material properties.

The recent years have opened greater possibilities for acrylic materials by realizing when heated, the molten materials turn out to be flexible materials that with proper design guidance can be transformed from flat sheets to desirable acrylic shapes and designs. By employing an ideal acrylic bending process, flat acrylic can be bent, which opens up endless possibilities for creating our acrylic articles and acrylic displays. Being the best alternative to glass and plastic sheets, the sheet of acrylic also has excellent compatibility and does not change color with simple bends. In everyday life, you may require to bend a piece of acrylic, for example, to create acrylic plates, medical devices, mobile phones, and jewelry holders. Hence, in this acrylic article, we’ve included some essential tips and techniques for bending acrylic sheets and the reasons why acrylic materials have wide acceptance in the market.

Table of Content

Acrylic Vs Glass

If ever an acrylic Vs glass debate arises, acrylic products can easily outstand the glass, for the durability and above all the bending property of acrylic achieved with acrylic bending machines. In recent years, there was a high advancement in acrylic fabrication services where acrylic sheet bending has acclaimed phenomenal popularity.

Unlike glasses, the possibility of breaking acrylic is nearly zero and hence it can be bent to desired shapes and structures considering the acrylic bending temperature. Moreover, if at any instance, wear or scratch occurs during the acrylic bending, removing scratches from acrylic sheets is effortless. With acrylic pieces, we can acquire a wide assortment of acrylic crafts, that showcase a broad spectrum of acrylic products with infinite possibilities for productivity. While glasses can acquire only linear shapes, the shapes and designs produced by bending acrylic are numerous ranging from oval shapes to zig zags. This serves to be the key difference between acrylic and glass.

Acrylic Cutting and Laser Engraving is a process of cutting acrylic into pieces of desirable shapes and sizes which can then be later adhered to by using acrylic glue to create acrylic products. Unlike glasses, cutting and bending acrylic is easier as it is less fragile and they are stretchable material and hence can be easily transformed into attractive shapes.

With technical advancements and the structural peculiarity of acrylic, various acrylic bending tools can be employed to bend the acrylic by heat.

Various Methods of Acrylic Bending

There are a plethora of options in acrylic bending, where we can employ either industrial methods or DIY acrylic bending machines to create innovative shapes and designs including acrylic boxes and nameplates. The line of acrylic bending machines covers products of various budgets and precision.

Conventional kitchen ovens and hair dryers are generally used acrylic bending machines in homes with which acrylic can be readily bent into desired shapes to make acrylic stands and other products. However, if accurate outlines and detailing is your intention, there are acrylic bending machines for sale that can bend your acrylic sheets to more precise measurements.

Let us briefly discuss the various bending machines in the market used for bending clear acrylic sheets as well as equipment used for bending large acrylic tubes. The list might include industrial equipment like acrylic line bending machines and DIY acrylic bending machines as well.

Bending Acrylic with Hair Dryer

If you have limited tools, you can bend the acrylic panels using a hairdryer. Before commencing the bending process, remove the protective coating from the acrylic. With an erasable pen or marker, make tool marks such as straight lines on the part to be bent. Slowly glide the hairdryer along the newly produced mark, ensuring even heating until it is in the required flexible state. Maintain a space of at least 5 cm between the dryer hole and the surface of the acrylic plate during the heating process. Gently tug the edge of the plexiglass sheet to test its flexibility on a regular basis. When acquired at the desired temperature, bend the acrylic to the correct angle. Ensure that the bending is done to the desired shape. Once bend, wait for a while for the piece of acrylic to get harder again. It should be placed idle until it is completely hardened.

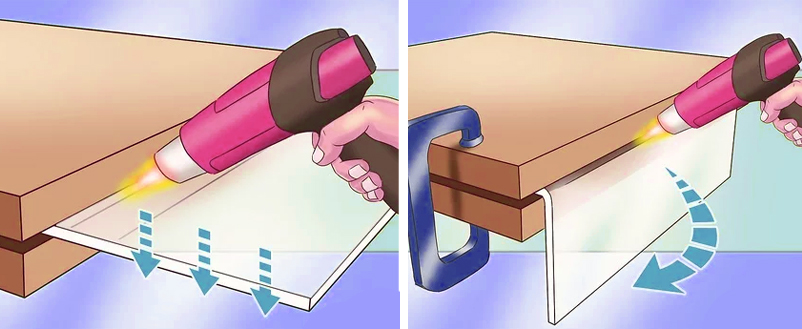

Bending Acrylic with Heat Gun

In terms of bending acrylic, hot air guns outperform hair dryers. After peeling off the protective film and taking preventive measures, we can start the bending procedure which is practically simpler. Determine the point at and angle to which the acrylic sheet is to be bent before clamping it on the acrylic bending jig. This necessitates planning the position of the curvature. Fix the acrylic board between two pieces of scrap wood using clamps, a vise, and other tools. Switch on the heat gun to gradually bend the acrylic. If you must make multiple bends, do it after the prior bend has cooled. This will greatly aid in retaining the contour of each bend.

Bending Large Acrylic Tubes

There are instances where you need to bend acrylic into large tubes, like an acrylic canopy or tubular aquariums, or even tubular utensils. Acrylic Line Bending Machines have acclaimed unparallel popularity for their efficiency in bending acrylic into sharp curves using the thermoforming technique.

If planning to make acrylic tubes at home, here is the technique that is to be followed. If the acrylic sheet includes a high temperature resistant protective film, you do not need to remove it or else remove the protective film. Place the acrylic sheet over a long, smooth filament, with the bend line exactly above the wire. When heated to 160 degrees Celsius, acrylic softens and bends readily. To avoid damaging the material on the outside of the fold, bend the acrylic gradually and carefully. After bending, slightly heat the exterior of the fold line to properly seal it. Allow the acrylic perspex to cool and harden in the desired shape. When cooled, the perspex retains its newly designed figure eternally. After the bending is achieved, seal the design with acrylic glue.

However, with DIY acrylic bending machines you can just make small utensils that too with less precision. If accurate design is your ultimate goal, industrial acrylic bending machines should be employed to get the desired outcome. Thermoforming entails heating the target material over its glass transition temperature with nichrome wire or infrared rods as the heating element. Heating is done at a very high temperature ranging from 230 F to 360 F. Then, by applying suitable pressure and force while still being hot, the large and thick acrylic sheets can be bent to desired shapes and designs. It is then cooled as the load is applied, preserving the shape and providing an exceptionally smooth surface. This technique is ideal for producing large acrylic aquariums and acrylic canopies.

Various Products made from Acrylic Bending

The list of products made with acrylic bending is infinite ranging from acrylic name plates and acrylic nails to acrylic furniture and acrylic canopies. Acrylic nails are a popular fashion statement in the fashion industry that offers stylish removable nails. Similarly, there are a wide variety of acrylic stands and acrylic boxes in the market that are perfect for showcasing premium products. Acrylic furniture has also gained popularity in recent years for the versatility in shapes it offers. We can employ acrylic bending techniques to make attention-seeking furniture that captivates the attention of the beholders. Make elite spaces have enormous aquariums made of acrylic that have live fishes in them. All these structures are devised to perfection by acrylic bending techniques.

Wrapping Up

Acrylic bending is a sophisticated, yet simple way of producing and creating acrylic in which the user can produce attractive acrylic designs with significant strength and endurance. Although there are a few DIY techniques for acrylic bending, commercial acrylic bending machines are the finest options for precise detailing. If ever a quest for ‘the best company for acrylic sheet bending near me’ arises in the minds of Emiratis with advanced and accurate acrylic bending services, Pleasant Acrylic serves to be an outstanding option.

Frequently Asked Questions

- How thick of acrylic can we bend using DIY techniques?

Most strip heaters can heat up to 1/4 ” thick acrylic for bending. If your acrylic is thicker than 1/4 inch it may not have been properly and uniformly heated by the DIY technique, making bending difficult and/or resulting in a twisted and uneven bend.

- Which acrylic letter bending machine is the best?

Name boards with carved letters can be made from acrylic sheets using either commercial or DIY acrylic bending techniques. Hair dryers may be the best choice for acrylic bending if you plan to make name boards at home.

- Is bending colored plexiglass sheet possible?

Yes, similar to bending clear acrylic sheets, the colored plexiglass sheets can also be bent to any desired angles and shapes.