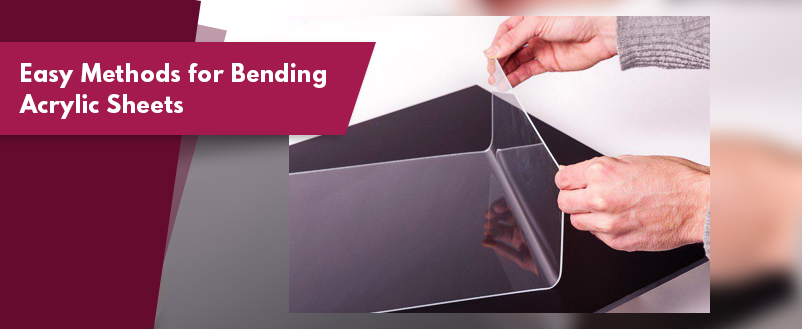

Acrylic sheets, renowned for their versatility and durability, have become a staple in various industries and DIY projects. Among the different applications, the ability to bend acrylic sheets opens up new possibilities in design and functionality. This article explores the fundamental art of bending acrylic, offering insights into the process and techniques that empower both professionals and enthusiasts. As we delve into the significance of bending acrylic sheets, we’ll also touch upon key considerations to ensure successful outcomes. Whether you’re a seasoned artisan or a newcomer to the world of acrylic manipulation, understanding these essentials will pave the way for seamless bending experiences. Explore the fascinating realm of acrylic bending with us, as we uncover easy and effective methods for achieving remarkable results. If you’re in Dubai and seeking quality acrylic sheets, choose reliable acrylic sheet suppliers in Dubai.

Table of Content

How to bend acrylic sheets?

To bend acrylic sheets effectively, start by sourcing high-quality materials from reputable Acrylic Sheet Suppliers in Dubai. Choose the appropriate bending method, such as heat bending with a heat gun or strip heater, utilizing an oven, or employing a DIY jig for precision. Ensure safety with protective gear like gloves and eyewear. Clamps or a straight edge aid in maintaining desired shapes. Trim the excess material with an acrylic cutter and finish with polishing compounds. For reliable results, follow these steps, combining expertise with quality materials from trusted Dubai suppliers.

List of Essential Tools:

A. Heat Source:

- Clamps or Jig:

- Clamps: Secure acrylic sheets in the desired position during the bending process, ensuring accurate and consistent bends.

- DIY Jig: A customized tool made from wood or metal, helping maintain the desired shape during bending.

- Straight Edge:

- Metal Ruler or Straight Edge: Ensures straight and precise bends, especially useful for cold bending techniques.

- Cutting Tools:

- Acrylic Cutter or Saw: Used for trimming excess material and cutting sheets to the desired size. If you are looking at “how to make a acylic box”, then you require these cutting tools.

- Measuring Tools:

- Ruler, Measuring Tape, or Combination Square: Essential for accurate measurements, ensuring the bends align with project specifications.

- Protective Gloves:

- Heat-Resistant Gloves: Necessary when handling heated acrylic to prevent burns or injuries.

- Ventilation:

- Good Ventilation System: Disperses fumes generated during the bending process, especially crucial when using heat sources.

B. Required Safety Equipment:

- Safety Glasses:

- Protective Eyewear: Shields eyes from debris, potential splinters, or any flying particles during cutting or trimming.

- Respirator:

- Respiratory Mask: Filters out fumes and ensures clean air while working with heated acrylic, protecting against respiratory issues.

- Protective Clothing:

- Long Sleeves and Pants: Minimize skin exposure to hot acrylic or sharp tools, reducing the risk of burns or cuts.

- Fire Extinguisher:

- Fire Safety Equipment: A precautionary measure in case of accidental fires, especially when working with heat sources.

C. Recommended Materials for the Process:

- High-Quality Acrylic Sheets:

- Acrylic Sheets: Choose sheets with the appropriate thickness for your project, ensuring they are of high quality for better results, especially during plastic fabrication in Dubai.

- DIY Jig Materials:

- Wood or Metal: Used to create a customized bending jig that suits the specific requirements of your project.

- Polishing Compounds:

- Polishing Compounds: Essential for finishing touches, helping achieve a smooth and polished surface on the bent acrylic. Acrylic UV Printing Service in Dubai makes use of this feature.

- Acrylic Adhesive:

- Adhesive: Optional but useful for bonding acrylic pieces together after bending, providing a seamless finish. This is beneficial in cases of acrylic podium in Dubai.

- Protective Film or Paper:

- Peel-Off Protective Film: Guards the acrylic surface from scratches or damage during the bending process, ensuring a pristine result.

For those in Dubai working on projects like acrylic name boards or intricate designs, sourcing high-quality acrylic sheets is crucial. Explore the diverse acrylic design landscape in Dubai, and connect with reputable suppliers to elevate your projects with top-notch materials.

Heat Bending Acrylic

Explanation of the Heat Bending Method:

Heat bending involves softening acrylic sheets with a heat source to make them pliable. This method allows for shaping the acrylic into desired forms.

Step-by-Step Guide for Heat Bending Acrylic Sheets:

- Prepare Workspace: Ensure proper ventilation.

- Secure Acrylic: Use clamps or a jig.

- Heat Application: Apply heat evenly using a heat gun or oven.

- Bend Carefully: Gently shape the acrylic to the desired form.

- Cooling Period: Allow the acrylic to cool and solidify in the desired shape.

Tips for Achieving Precise Bends:

- Maintain consistent heat application.

- Practice on scrap pieces for better control.

- Use an Acrylic Laser Cutting Service in Dubai for precise pre-cut shapes.

Line Bending Acrylic

Line bending is a method that involves heating a specific line on an acrylic sheet, making it pliable for bending. This technique is commonly used in Acrylic Design in Dubai.

Equipment Needed for Line Bending:

- Line bender or strip heater

- Clamps or a jig for securing the acrylic

- Protective gear: gloves and eyewear

Detailed Instructions for Line Bending Acrylic Sheets:

- Mark the Line: Mark the bending line on the acrylic.

- Secure the Sheet: Use clamps or a jig.

- Heat the Line: Apply heat evenly along the marked line.

- Bend Gradually: Gently shape the acrylic along the heated line.

Common Mistakes and How to Avoid Them:

- Uneven Heating: Ensure even heat distribution for consistent bends.

- Overheating: Avoid prolonged exposure to prevent warping or damage.

- Insufficient Securing: Use proper clamping to prevent unintended bends.

Oven Bending Acrylic

Oven bending utilizes controlled heat in an oven to soften acrylic sheets, allowing for precise shaping. This method is efficient for larger projects.

Setting up the Oven for Acrylic Sheet Bending:

- Preheat the oven to the recommended temperature.

- Use a dedicated rack or tray for even heating.

Step-by-Step Process for Oven Bending:

- Preparation: Secure the acrylic with clamps or a jig.

- Heating: Place the acrylic in the preheated oven.

- Monitoring: Keep a close eye on the acrylic’s pliability.

- Shaping: Remove and bend the acrylic as needed.

Safety Precautions While Using an Oven:

- Wear heat-resistant gloves and protective eyewear.

- Ensure proper ventilation in the workspace.

- Use an Acrylic Bending Machine for added precision and safety.

Finishing Touches

Finishing touches are essential, especially for acrylic cosmetic box in Dubai

A. Trimming Excess Material After Bending:

- Use an acrylic cutter to trim any surplus material from the bent acrylic sheets.

B. Smoothing Out Edges for a Professional Finish:

- Employ sandpaper or a fine file to achieve smooth and polished edges, enhancing the cosmetic box’s aesthetics.

C. Polishing and Cleaning the Bent Acrylic Surface:

- Apply a quality polishing compound to achieve a clear and glossy finish.

- Clean the acrylic surface to remove any residue, ensuring a pristine appearance for your handmade cosmetic acrylic box in Dubai.

Conclusion

In mastering acrylic bending, sourcing quality materials from trusted suppliers, like Acrylic Podium Suppliers in UAE, is paramount. Whether crafting signage or intricate designs, understanding essential tools and safety measures is crucial. Try out the creative process; experimentation and practice are the cornerstones of mastering acrylic bending. As you explore, consider consulting Dealers of Acrylic Plastic in UAE for expert insights and materials. The versatility of acrylic bending methods opens doors to limitless design possibilities. From signage to podiums, the journey is as rewarding as the finished product. Trust reputable Acrylic Signage Board Suppliers in Dubai for quality materials, and let your imagination bend the boundaries of acrylic craftsmanship.